Commissioning, maintenance and refurbishment

PPI Valves operates in the maintenance of oil and gas equipment throughout the upstream oil and gas production process, from wellhead production, to gathering, processing (compression and dehydration) and gas transmission facilities.

PPI Valves specialises in aftermarket support for a range of oil and gas processing equipment, including:

- Ball valves

- Globe valves

- Gate valves

- Non-return valves

- Valve actuation

- Valve control systems

- Reciprocating pumps

- Centrifugal pumps

- PSV/PRV

PPI Valves has in-house capability for general maintenance, refurbishment and provision of OEM and non-OEM spare parts. PPi Valves works with clients on reliability improvement projects to maximise value from assets and minimise unplanned downtime and repair times.

PPI Valves can maintain clients’ equipment either from our Miles or Sunshine coast workshops or on site, with personnel embedded within a client organisation.

EXPERIENCE IN VALVE CONTROL

PPI Valves has established service partnerships with several leading valve, actuation and control provider. This allows PPI Valves direct access to spares inventory at the best available prices and support from the OEM..

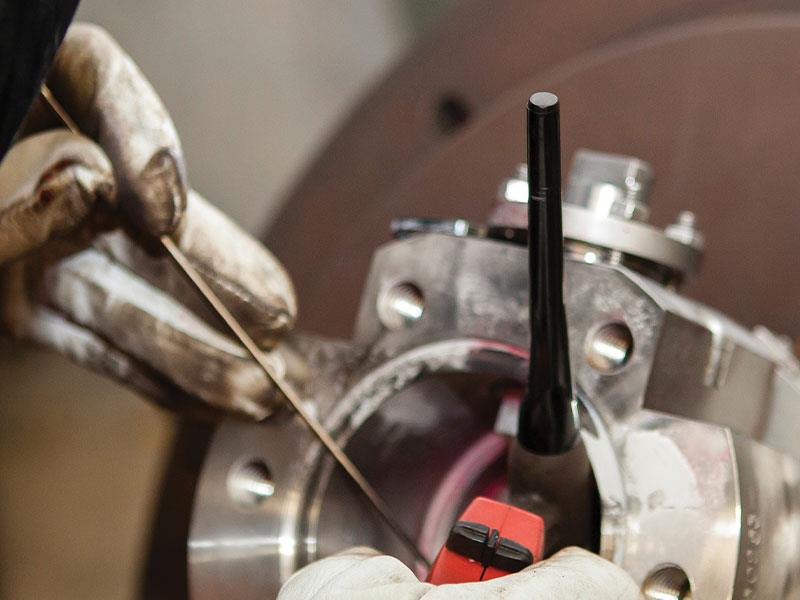

SPECIALISED ALLOY EXOTIC WELDING

Developed out of the requirement to produce an updated trim kit for our clients, PPI Valves has established a team of exotic alloy welders matched to a suite of PPI Valves owned welding procedures.

As well as conventional carbon and stainless-steel capabilities, our team are qualified to weld Titanium, Super Duplex, Duplex and Inconel Stainless Steels variants. Other aspects we can tackle include Tantalum, Tungsten Carbide and Alloy linings of piping, valves, pump heads and dissimilar clad metal plate work. We tackle the complex weld repairs on process plants and valve components to refurbish clients equipment back to OEM standards.

embracing technology

PPI Valves continues to challenge the status quo and look for emerging technologies to complement the effectiveness of our deliverables.

In addition to our standard fare of engineering machinery, our Queensland facility employs such technology as:

-

3D Romer Arm coordinate measuring machine (CMM) inspection

-

Ultrasonic solvent cleaning

-

Vapour grit blast cleaning

- Oxygen cleaning

-

Dot peening name plate marking

-

API certified valve hydro-testing

- Pressure testing and calibration of PSV, PORV